Crushing Screening Plants

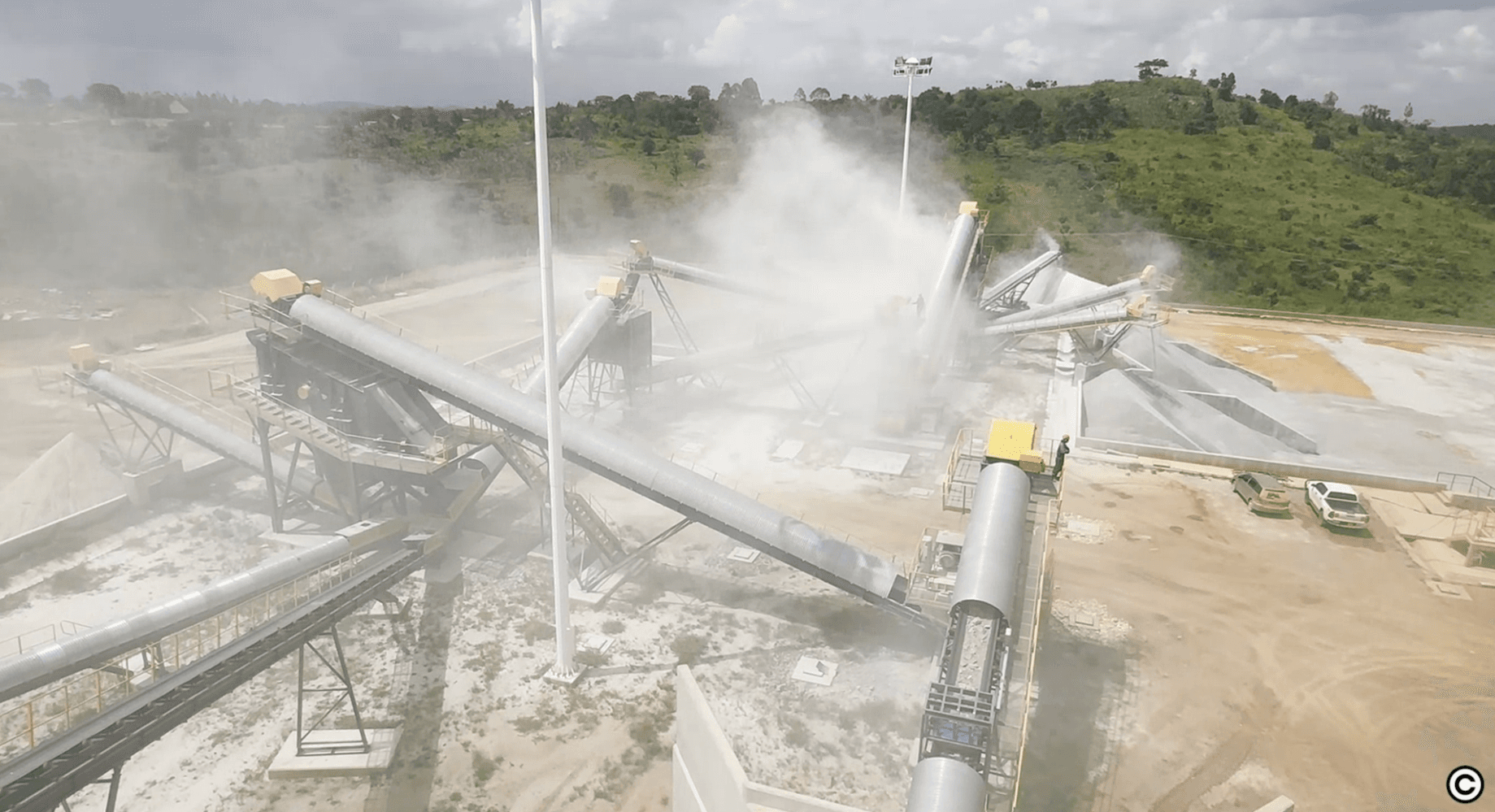

Dust Suppression & Dust Control Solutions

ENVEX offers single-fluid and dry fog dust suppression systems designed for feeding hoppers, primary, secondary and tertiary crushers, VSI crushers, cone crushers, conveyor belt transfer points, fine processed raw material stockpile drop conveyors and domes in crushing and screening plants.

In addition, ENVEX fog cannon dust suppression systems are utilized for raw material truck loading and unloading operations, effectively preventing dust generation during handling. Fog cannons are also applied in stockyards to minimize dust emissions caused by wind effects.

Limestone Crushing &

Screening Plant Dust Control

Limestone crushing for cement and aggregate production generates a high amount of fine dust particles.

Iron Ore Crushing &

Screening Plant Dust Control

The abrasive nature of iron ore dust causes severe wear on equipment, especially at conveyor transfer points and stockpile discharge areas.

Copper Ore Crushing &

Screening Plant Dust Control

In copper mining, dust is not only a health hazard but also a loss of valuable material unless it is effectively controlled.

Jaw Crusher Dust Suppression Application

Jaw Crusher Dust Suppression Application

Dust control and suppression solutions for jaw crushers.

Gyratory Crusher Dust Suppression Application

Dust control and suppression solutions for gyratory crushers.

Primary Crusher Stockpile Dust Suppression Application

Dust control and suppression solutions for primary crusher stockpiles.

Cone Crusher Dust Suppression Application

Dust control and suppression solutions for cone crushers.

VSI Crusher Dust Suppression Application

Dust control and suppression solutions for VSI crushers.

Tertiary Crusher Dust Suppression Application

Dust control and suppression solutions for tertiary crushers.

Conveyor Belt Transfer Points Dust Suppression Application

Dust control and suppression solutions for conveyor belt transfer points.

Bunker Loading Dust Suppression Application

Dust control and suppression solutions for bunker loading.

Dome Dust Suppression Application

Dust control and suppression solutions for domes.